H2S Removal from Biogas 2026 – Technology Review

Biogas plant operators and renewable natural gas (RNG) producers continue to face a critical challenge in 2026: hydrogen sulfide (H₂S). This corrosive and toxic gas can damage equipment, corrode engines, fail strict pipeline specifications (typically [...]

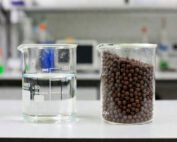

H2S Scavenger Cost Comparison: Triazine vs Iron-Based Adsorbents

Two of the most common non-regenerative approaches are triazine-based liquid scavengers (typically MEA or MMA triazine) and iron-based adsorbents (such as iron oxide/hydroxide or iron sponge media). But which one delivers the lowest true cost [...]

Top 5 H2S Removal Methods for Oil and Gas

In the oil and gas industry, hydrogen sulfide (H₂S) — also known as sour gas — is a highly toxic, corrosive, and dangerous contaminant found in crude oil, natural gas, and associated water streams. Even [...]

MEA Triazine vs MMA Triazine vs Non-Triazine H₂S Scavengers

Hydrogen sulfide (H₂S) remains one of the most dangerous and costly challenges in oil and gas operations. Toxic, corrosive, and tightly regulated, even low levels can shut down pipelines, poison refinery catalysts, trigger permit violations, [...]

Amines and Absorbents in Amine Gas Treating

Amine gas treating — also called gas sweetening or acid gas removal — is the workhorse technology for removing hydrogen sulfide (H₂S) and carbon dioxide (CO₂) from natural gas, refinery streams, biogas, and syngas. At [...]

Optimizing the Claus Process

Figure 1: Typical Claus process flow diagram showing thermal furnace, waste heat boiler, catalytic reactors and condensers (Public domain – Wikimedia Commons). The Claus process stands as the cornerstone of sulfur recovery in the oil [...]