Article Content

- 1. Detection and Monitoring: Foundation of All Controls

- 2. Chemical Scavenging: Primary Treatment to Reduce H₂S at Source

- 3. Engineering Controls: Inerting, Vapor Recovery, and Containment

- 4. Operational Procedures and PPE Integration

- 5. Common Operational Challenges and Mitigation Effectiveness

- Conclusion: Integrated, Layered Approach Delivers Safety

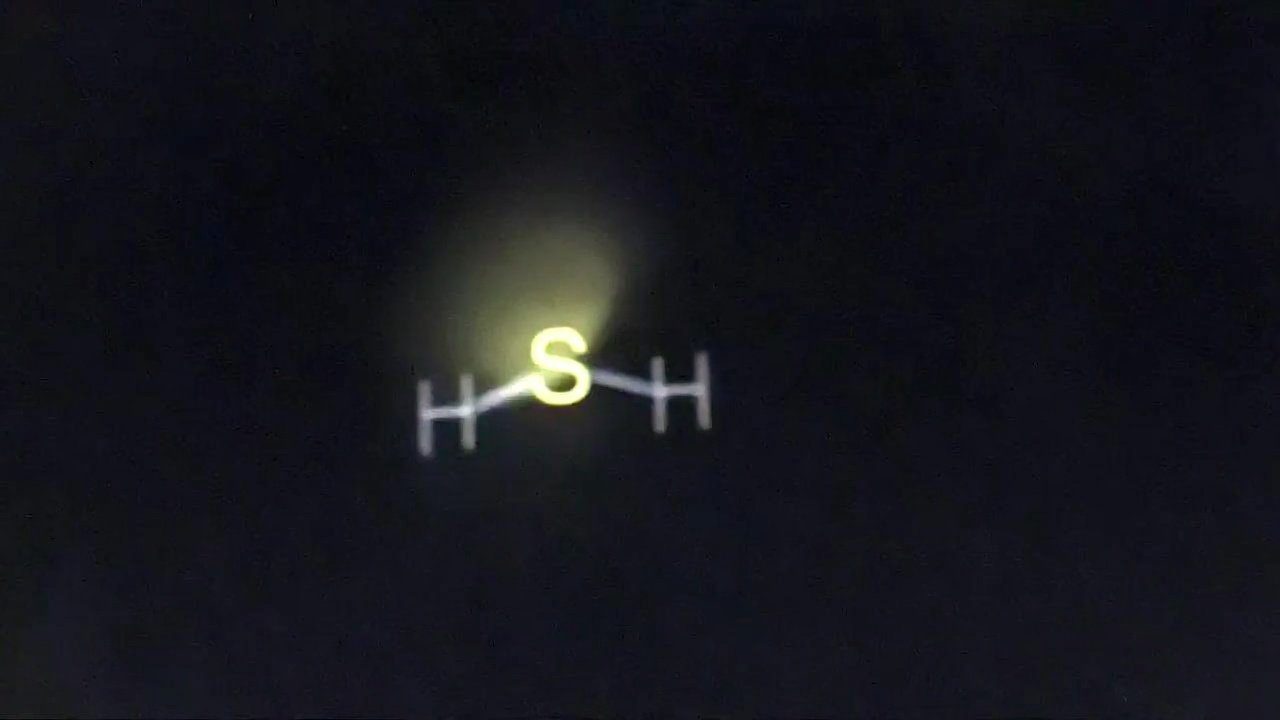

Hydrogen sulfide (H₂S) remains one of the most persistent and dangerous challenges in transporting sour crude oil and petroleum products. This colorless, heavier-than-air gas (density 1.19 relative to air) evolves rapidly from liquid-phase H₂S during loading and unloading due to agitation, pressure drops, temperature fluctuations, and splashing. These phases account for the highest exposure risks, as tanks are opened or pressurized, vapors are displaced, and residues/sludge release trapped gas. Liquid H₂S (measured in mg/kg or ppmw via IP 570 or ASTM equivalents) can generate vapor concentrations 50–100 times higher or more, depending on crude properties.

Industry manages H₂S through a strict hierarchy of controls: detection and monitoring, chemical scavenging, engineering systems (inerting, vapor recovery), procedural safeguards, and PPE as backup. Standards include ISGOTT (International Safety Guide for Oil Tankers and Terminals, 6th ed.), 49 CFR for rail (PHMSA/DOT/AAR), IMO/SOLAS for marine, OSHA exposure limits (typically 10 ppm TWA, 20 ppm ceiling in many jurisdictions), and terminal-specific rules (e.g., <5–10 ppm vapor often enforced). Marine fuels/bunkers are capped at ≤2 mg/kg liquid H₂S (ISO 8217), while rail often rejects or treats cargoes exceeding 5–10 ppm vapor headspace.

This guide focuses on practical methods and techniques used in rail tank car and marine tanker operations, detailing how treatments work, application points and frequencies, effectiveness, and common issues encountered in real-world loading/unloading.

1. Detection and Monitoring: Foundation of All Controls

Accurate, timely measurement drives every decision. Loading/unloading cannot proceed without verified low H₂S levels.

- Liquid-Phase Testing: IP 570 (or ASTM D7621/UOP 163) quantifies dissolved H₂S in crude. Performed at production, storage, and pre-transfer. Results guide scavenger dosing.

- Vapor/Headspace Testing: ASTM D5705 “Can Test” is the gold standard for transportation safety. Procedure: Fill a sealed bottle with sample, agitate/heat to simulate conditions, then use colorimetric detector tubes or electronic sensors on the headspace. Conducted on every rail car compartment or tanker tank pre-arrival and pre-loading/unloading. Rail facilities test each car; marine terminals test each cargo tank.

- Field Tools:

- Personal wearable electronic monitors (e.g., with 5–10 ppm alarms) worn by all personnel during ops—continuous real-time.

- Fixed multi-gas sensors on manifolds, decks, and low points.

- Draeger tubes or sniffers for spot checks.

- Online analyzers (KECO Model 205 series) for continuous inline measurement during pumping.

Frequencies

- Pre-operations: Mandatory per car/tank before any opening or connection.

- During loading/unloading: Continuous personal monitoring; fixed systems sample every 1–5 minutes.

- Marine-specific: Regular ullage space checks on cargo/slop tanks (even “empty” ones), often daily or per shift, using specialist high-range equipment.

- Post-operations: Re-test after stripping or cleaning to confirm residuals.

Common Issues: Olfactory fatigue (smell lost >100 ppm), sampling errors (H₂S partitions unevenly; must sample at multiple heights), batch variability (sweet crude can turn sour en route), and under-detection in high-water-cut crudes where bacteria generate fresh H₂S.

2. Chemical Scavenging: Primary Treatment to Reduce H₂S at Source

Scavengers chemically bind H₂S into stable, non-volatile, non-toxic compounds, preventing vapor release. They are the most common proactive treatment for sour cargoes.

Main Types and How They Work

- MEA-Triazine (most common): Water-soluble, fast-reacting aldehyde-amine. Reacts irreversibly: H₂S + triazine → dithiazine (stable byproduct) + water/ammonia traces. Effective in liquid and multiphase systems.

- Non-Triazine Alternatives (e.g., Q2 Pro3®, Vink stabicor® S-series glycol/aldehyde blends, iron-based): Oil-soluble or hybrid; higher capacity (2:1 to 15:1 scavenger:H₂S ratio), lower nitrogen (avoids downstream salt fouling), minimal solids/polymers. Some handle up to 180°C.

Application Techniques

- Injection Points: Directly into transfer pipelines, loading manifolds, or drop lines at gathering stations, terminals, or ship/truck racks.

- For Loading: Injected upstream of the loading arm—ensures contact time (minutes) before cargo enters tank car or tanker.

- For Unloading: Sometimes re-dosed at discharge if regeneration occurred in transit.

- Marine: Added to cargo/slops or ullage; in-transit treatment on FPSOs via containment systems.

- Rail: Pre-load at origin or terminal racks; post-unload if residuals high.

Dosage & Frequencies

Lab assay determines base stoichiometric requirement, plus 10–50% excess. Optimized via online analyzers for real-time adjustment.

- High-sour cargoes (>10–100 ppm vapor): Continuous proportional dosing during entire loading (treat to <10 or 0 ppm before acceptance).

- Routine: Batch at storage or single injection per transfer for moderate levels.

Effectiveness: Reduces liquid H₂S to <2 mg/kg (marine spec) and vapor to safe levels in hours. Prevents corrosion and meets terminal rejection thresholds.

Common Issues:

- Incomplete mixing in viscous crudes (requires good turbulence).

- Byproduct handling (fouling filters/pumps if over-dosed).

- Regeneration if scavenger depletes (bacteria or heat breaks byproducts).

- Cost and compatibility (some interfere with refining catalysts).

3. Engineering Controls: Inerting, Vapor Recovery, and Containment

Marine Tankers (ISGOTT-Driven)

- Inert Gas System (IGS): Flue-gas or membrane-generated inert gas (O₂ <5–8%) maintains positive pressure in tanks at all times. Operates continuously during loading/unloading/voyage. Frequency: Always on for loaded or partially loaded tanks; monitored hourly for O₂/H₂S/LEL.

- Vapor Control System (VCS/VECS): Closed loading—vapors displaced to shore VRU, scrubber (caustic/amine for H₂S), flare, or incinerator. Mandatory for high-H₂S cargoes.

- Closed Operations: Fixed gauging, vapor-tight sampling; slow initial fill rates to submerge inlets.

Rail Tank Cars

- Vapor Recovery Units (VRU) at Terminals: Compression/absorption/oxidation systems capture 95–99% vapors during loading/unloading, with dedicated H₂S scrubbers.

- Nitrogen Padding/Blanketing: Post-loading or during pressure relief—N₂ displaces air, suppresses evolution. Applied per car after filling or before unloading.

- Closed Bottom Loading: Preferred; vapor valve connected first.

Common Issues:

- H₂S Regeneration: Sulphate-reducing bacteria (SRB) in high-water-cut oil/sludge produce fresh H₂S in ullage spaces (up to 16,000 ppm reported). Agitation during voyage or heating spikes levels. Sludge reduces tank capacity 5–20% and accelerates corrosion.

- Pyrophoric Iron Sulfides: Form in inert conditions; ignite spontaneously on air contact during gas-freeing or maintenance.

- Vent Dispersion: Poor wind causes low-level accumulation.

- Corrosion: Sour service causes “bath-ring” pitting along rail car bottoms. Requires ultrasonic thickness testing every 5–10 years.

4. Operational Procedures and PPE Integration

Pre-transfer conferences exchange H₂S data. Loading/unloading plans specify rates, wind monitoring (stand perpendicular/upwind), ESD activation on alarms. Buddy system mandatory. Rail: Placard “Sour Crude” (skull/crossbones) if inhalation hazard. Marine: Risk assessments for >100 ppm trigger enhanced PPE.

PPE: Personal H₂S alarms always; SCBA/supplied-air respirators for gauging, sampling, or >10 ppm zones. Eyewash/showers at sites.

5. Common Operational Challenges and Mitigation Effectiveness

- Batch Variability & Spikes: Crude from different fields mixes unpredictably. Solution: Multi-point testing + on-demand scavenging.

- Sludge and MIC: Primary cause of regeneration/corrosion. Mitigation: Periodic tank cleaning, biocides alongside scavengers.

- Corrosion in Rail Fleet: Sour crude accelerates internal damage.

- Exposure Incidents: Often from breaching containment without monitoring.

- Regulatory/Terminal Differences: Some facilities reject >5 ppm; others allow treated cargoes.

Innovations Improving Outcomes: Online analyzers for automated dosing; non-triazine scavengers; bio-scavengers; AI-predictive monitoring of sludge; advanced high-range H₂S sensors.

Conclusion: Integrated, Layered Approach Delivers Safety

Effective H₂S management during rail and marine oil loading/unloading combines real-time monitoring (pre-every transfer, continuous ops), targeted chemical injection (continuous for high-risk, at manifolds/pipelines), robust engineering (IGS always-on for ships, VRU/N₂ for rail), and disciplined procedures. These techniques routinely reduce risks to near-zero when followed rigorously—preventing fatalities, corrosion failures, environmental releases, and operational downtime.

Challenges like bacterial regeneration and variable crude quality persist but are managed through frequency-driven testing and multi-layered controls. Operators investing in online optimization and training achieve the best results. As sour crudes continue in global supply chains, these proven methods ensure safe, efficient transportation while protecting workers, assets, and communities.