While the two processes share the same core chemistry, they differ significantly in contacting technology, equipment design, footprint, economics, and ideal applications. This article provides a detailed comparison to help operators choose the best fit for their feedstock, scale, and site constraints.

Shared Chemistry: The Foundation

Both Merox and Mericat rely on the same fundamental reactions:

Deprotonation: RSH + NaOH → RSNa + H₂O

Catalytic oxidation: 4 RSNa + O₂ + 2 H₂O → 2 RSSR + 4 NaOH

Net: 2 RSH + ½ O₂ → RSSR + H₂O

A metal phthalocyanine sulfonate catalyst (usually cobalt-based) facilitates oxygen transfer, allowing in-situ regeneration of caustic with very low net consumption (typically 0.1–0.5 lb/bbl). The resulting disulfides remain dissolved in the hydrocarbon, providing permanent sweetening without producing elemental sulfur or requiring disposal streams.

Process Design & Equipment Differences

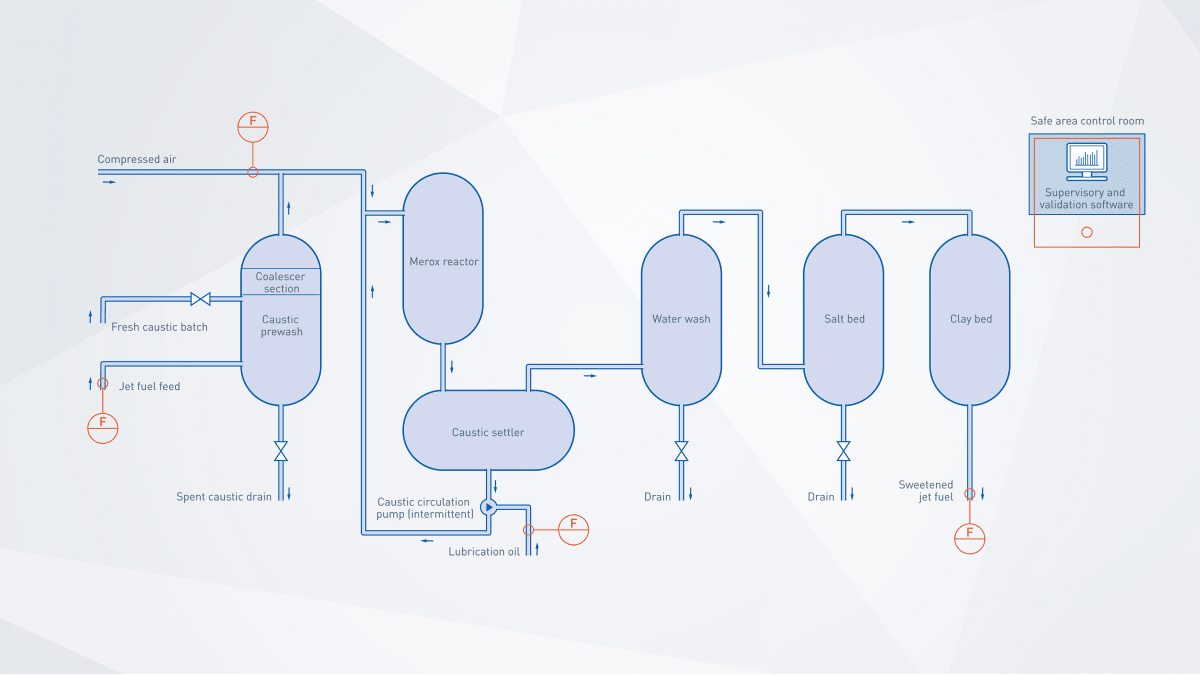

Merox (UOP) uses conventional liquid-liquid mixing or fixed-bed contacting, with dispersed phases and separate settlers/coalescers to handle emulsions.

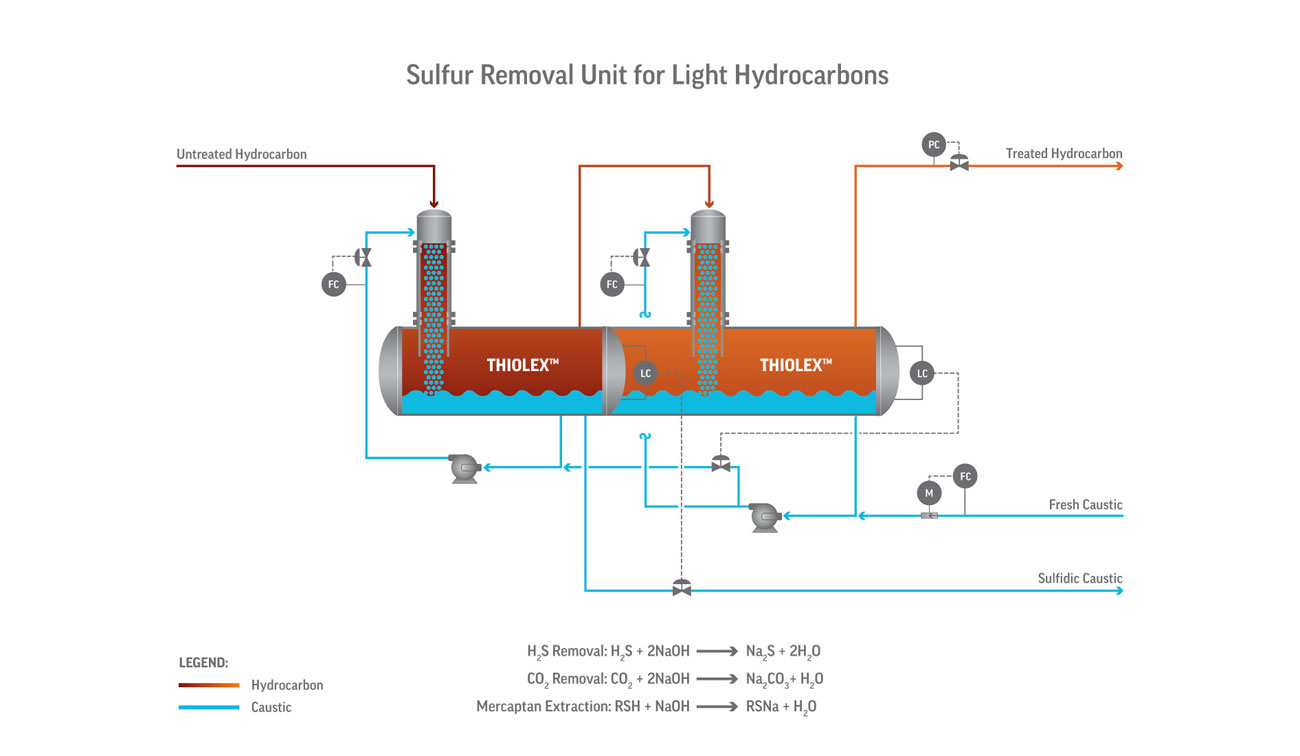

Mericat (Merichem) employs the proprietary non-dispersive FIBER FILM® Contactor, where caustic forms a thin film on hydrophilic fibers for superior mass transfer and minimal emulsion risk.

Comparison Table: Key Similarities & Differences

| Aspect | Merox (Honeywell UOP) | Mericat (Merichem) |

|---|---|---|

| First Commercialized | 1960s | 1977 |

| Number of Units (approx.) | Thousands worldwide | 70+ licensed |

| Contacting Technology | Dispersed mixing / trays / fixed-bed | Non-dispersive FIBER FILM® Contactor |

| Emulsion Risk | Moderate–high (needs settlers/coalescers) | Very low |

| Footprint & CAPEX | Larger for equivalent capacity | More compact / lower CAPEX |

| Best For | Large refineries, LPG extraction, legacy units | Revamps, space-limited sites, heavier mercaptans |

| Variants | Extraction, sweetening, Minalk fixed-bed | Mericat™, Mericat™ II, Mericat™ J |

| LPG/Gas Handling | Yes (extraction mode) | Primarily liquids |

When to Choose Which Technology

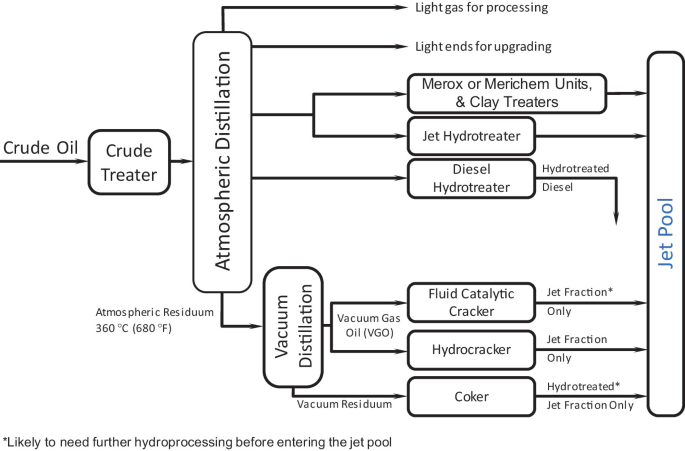

- Choose Merox if you operate a large, integrated refinery with existing UOP infrastructure, need LPG mercaptan extraction, or are replacing/expanding legacy sweetening units.

- Choose Mericat if you want lower capital cost, smaller footprint, modular design, or are treating heavier/branched mercaptans in naphtha, condensate, or jet fuel streams.

Conclusion

Merox and Mericat both deliver reliable, cost-effective mercaptan sweetening using proven caustic-oxidation chemistry, yet their engineering approaches lead to meaningful differences in layout, operability, and economics. For facilities in the Houston metropolitan area (including Sugar Land), both technologies are actively used—often side-by-side in different units. The right choice depends on feedstock composition, required throughput, available plot space, and long-term OPEX goals. Most licensors offer lab treatability studies to provide side-by-side performance predictions for your specific stream.