The Thiopaq system, developed by Paques in collaboration with Shell and universities, is a biological desulfurization technology designed to remove hydrogen sulfide (H₂S) from gas streams, such as biogas, natural gas, and industrial gases. By using naturally occurring sulfide-oxidizing bacteria, like Thiobacilli, it combines H₂S absorption with biological sulfur recovery in a single process, producing biosulfur and sweet gas. Since its commercialization in the 1990s, over 200 installations have been commissioned, primarily for biogas desulfurization, with applications in oil and gas and other industries. This article explores the key advantages and limitations of the Thiopaq system, offering insights into its operational, economic, and environmental aspects.

Benefits of the Thiopaq System

1. Environmental Sustainability

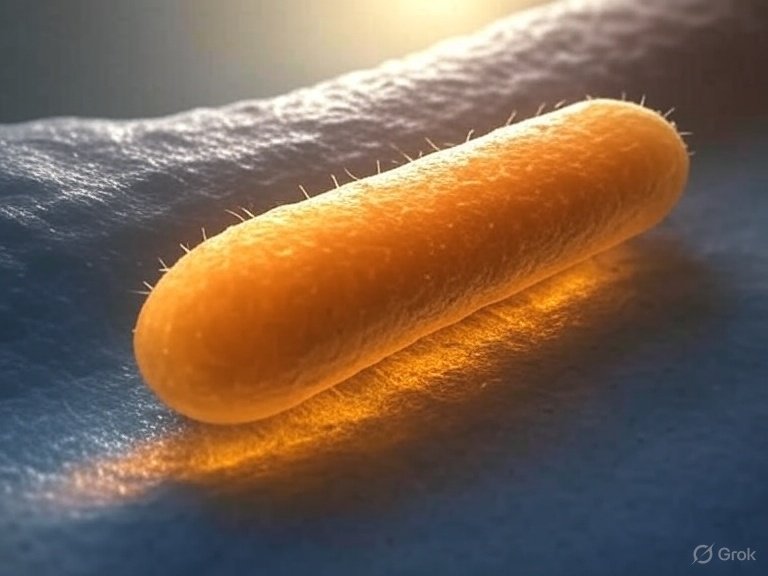

The Thiopaq system is an eco-friendly alternative to traditional H₂S removal methods, such as amine sweetening or Claus processes. It employs non-hazardous, naturally occurring bacteria to oxidize H₂S into elemental sulfur, eliminating the need for toxic chemicals. The process produces biosulfur, a hydrophilic product suitable for use as a high-quality organic fertilizer or fungicide, unlike the hydrophobic sulfur from chemical processes that can cause clogging. Additionally, Thiopaq can contribute to decarbonation by capturing CO₂ alongside sulfur recovery, aligning with stringent environmental regulations.

2. High H₂S Removal Efficiency

Thiopaq achieves exceptional H₂S removal efficiency, often exceeding 99.5%, reducing H₂S concentrations to below 25 ppm, even with inlet concentrations ranging from 100 ppm to 100 vol%. This high efficiency ensures compliance with pipeline specifications, making the treated gas suitable for gas engines, boilers, or upgrading to biomethane. The system’s ability to handle large fluctuations in gas flow and H₂S concentrations enhances its reliability across various applications.

3. Low Operational Costs

The Thiopaq system regenerates approximately 90% of its caustic washing solution biologically in the bioreactor, reducing the need for frequent chemical replenishment. This leads to significant cost savings compared to non-regenerative methods like triazine scavengers. Studies show that Thiopaq’s operational costs are lower than those of traditional liquid redox processes, particularly for small to medium-scale sulfur recovery (1–20 tons per day). The minimal waste produced, including a sulfide-free bleed stream and biosulfur, is suitable for disposal or reuse, further reducing costs.

4. Operational Flexibility

Thiopaq operates effectively across a wide range of gas pressures (0.1–7.5 MPa) and H₂S concentrations, making it versatile for applications in biogas, natural gas, syngas, and geothermal gas. Its ability to treat both low- and high-pressure gases without complex equipment or high energy inputs simplifies operations. The system’s ambient temperature and atmospheric pressure conditions in the bioreactor reduce energy demands, making it suitable for industries like pulp and paper, food and beverage, and biofuels.

5. Robust and Safe Process

The bacteria used in Thiopaq are naturally occurring, non-genetically modified, and highly resistant to varying process conditions. Since the first unit was commissioned in 1993, no colony replacements have been required, demonstrating the robustness of the microbial population. The absence of toxic chemicals and the production of non-hazardous biosulfur enhance operational safety, reducing risks to personnel and the environment.

Drawbacks of the Thiopaq System

1. High Capital Costs

While Thiopaq offers lower operational costs, its initial capital investment can be higher than some competing technologies, particularly for high-pressure or high-sulfur-load applications. Economic studies indicate that Thiopaq’s capital costs are competitive only in intermediate and low-pressure cases, making it less cost-effective for large-scale sulfur recovery (e.g., >50 tons per day) compared to amine and Claus processes. This limits its adoption in large-scale oil and gas operations.

2. Complexity in Redox Control

The efficiency of the Thiopaq system relies on precise redox control within the bioreactor. Maintaining optimal conditions for bacterial activity, such as aeration and pH (8–9), requires careful monitoring and process management. Deviations can affect biosulfur quality and quantity, potentially reducing system performance. Advanced mathematical modeling and computational fluid dynamics are recommended to optimize bioreactor performance, adding to operational complexity.

3. Limited Scalability for High Sulfur Loads

Thiopaq is most effective for small to medium-scale sulfur recovery (1–20 tons per day), making it less economically viable for high sulfur load capacities. For large-scale operations, traditional methods like Claus plants remain more cost-effective due to their ability to handle larger sulfur quantities efficiently. This scalability constraint restricts Thiopaq’s application in major oil and gas fields with high H₂S content, such as the Shah field in Abu Dhabi.

4. Dependence on Biological Systems

The reliance on biological processes introduces variability, as bacterial performance can be influenced by operating parameters like temperature, pH, and gas composition. While the bacteria are robust, unexpected fluctuations or suboptimal conditions may require adjustments, complicating operations compared to purely chemical processes. Further research is needed to enhance the predictability and control of biological desulfurization.

5. Limited Decarbonation Potential

Although Thiopaq offers simultaneous decarbonation with sulfur recovery, its CO₂ capture capabilities are not fully optimized. Current research suggests that deeper investigation into its decarbonation potential is needed to make it a viable solution for large-scale carbon capture applications, particularly in industries aiming to meet stringent carbon emission targets.

Conclusion

The Thiopaq liquid redox system is a sustainable and efficient solution for H₂S removal, particularly for small to medium-scale applications in biogas, oil and gas, and other industries. Its environmental benefits, high removal efficiency, low operational costs, and operational flexibility make it a compelling choice for meeting regulatory requirements and producing valuable biosulfur. However, high capital costs, complexity in redox control, limited scalability for high sulfur loads, and dependence on biological systems present challenges that may restrict its adoption in certain scenarios. Future advancements in bioreactor modeling and decarbonation capabilities could further enhance its competitiveness, making Thiopaq a cornerstone of sustainable gas treatment technologies.

For industries seeking a balance between environmental sustainability and operational efficiency, Thiopaq offers significant advantages, but careful consideration of project scale and economic constraints is essential before implementation.